|

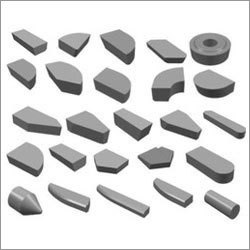

Solid Carbide Tools

Solid Carbide Tools Specification

- Tungsten( in %)

- 85%

- Carbon %

- 0.5%

- Diameter

- 2 mm - 20 mm

- Application

- Milling, Drilling, Turning

- Coating Type

- TiN (Titanium Nitride)

- Accessories

- Tool Case Included

- Flute Type

- Straight and Helical

- Cutting Edge Length

- Various as per requirement

- Packaging Type

- Individual Protective Cassette

- Material

- Solid Carbide

- Heat Resistance

- Up to 800°C

- Hardness

- ISO Grade HRC 90+

- Tolerance

- ±0.01 mm

- Precision

- High Precision Finish

About Solid Carbide Tools

We are engaged in offering Solid Carbide Tools, which is widely supplied by us to our prestigious clients in various ranges. These products are highly resistant to abrasive wear because of being thermally stable. Its designing and development is based on the advanced level of technology. It is equipped with several features such as long-lasting functional life, highly efficient, easy to install, and accurate in its dimensions. Our provided Solid Carbide Tools come with the feature of cutting edge hardness.

Product details

|

Packaging Type |

Box |

|

Hardness |

55 to 60 HRC |

|

Diameter |

5 - 20 mm |

|

Corrosion Resistance |

Yes |

|

Material |

Solid Carbide |

|

Usage/Application |

Industrial |

Robust ISO Grade Solid Carbide Construction

With a solid carbide base and a high tungsten content of 85%, these tools provide superior strength, hardness, and longevity. Designed to withstand intensive industrial operations, they ensure consistent quality in machining tasks by resisting deformation and wear.

Tailored for Precision Machining

Achieve remarkable accuracy with high-precision finishing and a tight tolerance of 0.01 mm. Whether the cutting edge length is standard or custom-designed, these tools deliver reliable performance in applications demanding meticulous detail.

Advanced Heat and Wear Resistance

The application of TiN coating and resilience up to 800C ensures that Solid Carbide Tools remain sharp and functional under extreme conditions. This feature extends tool life and optimizes productivity across diverse manufacturing environments.

FAQs of Solid Carbide Tools:

Q: How should Solid Carbide Tools be used for best results?

A: To obtain optimal performance, ensure the tool is selected based on the applicationmilling, drilling, or turningand securely fit in compatible machines. Using correct cutting parameters and proper cooling enhances tool life and precision.Q: What machining processes are these tools compatible with?

A: Solid Carbide Tools are suitable for a variety of machining processes, including high-precision milling, drilling, and turning tasks. They perform exceptionally well in operations requiring tight tolerances and fine surface finishes.Q: When is it advisable to choose TiN-coated Solid Carbide Tools?

A: TiN-coated tools should be selected when operations demand enhanced wear resistance, minimal friction, and the ability to withstand elevated temperatures up to 800C, particularly in high-speed or high-stress machining.Q: Where are these tools typically supplied and distributed in India?

A: Solid Carbide Tools are distributed, exported, imported, and supplied by manufacturers, wholesalers, distributors, and traders across India, serving a broad range of industrial and manufacturing sectors.Q: What is the process involved in manufacturing Solid Carbide Tools?

A: Manufacturing involves carbide powder consolidation, sintering at high temperatures, precise machining for edge creation, application of TiN coating, and rigorous quality checks for hardness and dimensional tolerance.Q: What benefits do individual protective cassettes and tool cases provide?

A: The protective cassettes and tool cases ensure each tool remains free from physical damage and dust, facilitating safe transportation, organized storage, and longevity of the tools cutting edges.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbide Tools And Inserts Category

TaugeTac Tools

Application : Industrial cutting and drilling

Diameter : Various diameters available

Tungsten( in %) : Tungsten carbide components

Warranty : Manufacturer warranty provided

Coating Type : Advanced coating for durability

Accessories : Multiple drill and cutting tools

Rolling Mill Carbide Insert

Application : Used in rolling mill operations and metal shaping

Diameter : Variable depending on type

Tungsten( in %) : High tungsten percentage for durability

Warranty : 1 year manufacturer warranty

Coating Type : Uncoated

Accessories : Carbide inserts variety for rolling mills

Mitsubishi Tools

Application : Milling, Drilling, Cutting in Industrial Machining

Diameter : 4mm 20mm

Tungsten( in %) : 8%

Coating Type : TiAlN (Titanium Aluminum Nitride)

Accessories : Included Tool holder, user manual

|

ALDRICH INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |